In-depth Guide to Selecting the Right Shrink Film Machine for Your Business

Choosing the appropriate shrink film machine is crucial for businesses aiming to optimize their packaging processes. Whether you’re in manufacturing, distribution, or retail, selecting the right machine can significantly impact efficiency, product presentation, and overall costs. This guide delves into various factors businesses should consider when investing in a shrink film machine tailored to their specific needs.

Understanding Shrink Film Machines

Shrink film machines are vital in packaging industries for securely wrapping products using heat-shrinkable films. These machines offer flexibility in packaging various products, from food items to industrial goods, ensuring they are protected during transit and displayed attractively on shelves.

Types of Shrink Film Machines

1. Manual Shrink Wrap Machines: Manual machines are suitable for small-scale operations or businesses with limited production volumes. These machines require manual feeding and sealing of products into the shrink film before heat application.

2. Semi-Automatic Shrink Wrap Machines: Ideal for medium-sized enterprises, semi-automatic machines automate the sealing process but require manual loading and unloading of products. They are suitable for businesses looking to enhance packaging efficiency without full automation.

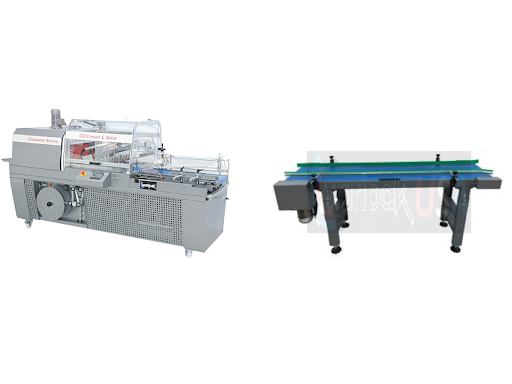

3. Automatic Shrink Packing Machines: Designed for high-volume production environments, automatic shrink packing machines streamline the entire packaging process. These machines automate product feeding, film sealing, and heat shrinking, significantly increasing throughput and reducing labor costs.

Factors to Consider When Choosing a Shrink Film Machine

1. Production Volume: Evaluate your daily output requirements to determine whether a manual, semi-automatic, or automatic machine suits your production volume. High-volume operations benefit most from automatic machines due to their speed and efficiency.

2. Product Dimensions and Shapes: Consider the size, shape, and weight of your products. Some machines are better suited for packaging irregularly shaped items, while others are ideal for standard box-shaped products.

3. Film Compatibility: Ensure the machine is compatible with the type and size of shrink film you intend to use. Different films have varying thicknesses and shrink ratios, affecting the final appearance and protection of packaged goods.

4. Operational Ease and Maintenance: Evaluate the ease of operation and maintenance requirements of the machine. Training staff on machine operation should be straightforward, and routine maintenance tasks should not disrupt production schedules.

5. Space and Layout: Consider the physical space available in your facility for installing the shrink film machine. Automatic machines may require more floor space and additional utilities like compressed air for operation.

Benefits of Investing in Automatic Shrink Packing Machines

-

Automatic machines offer higher packaging speeds and consistency compared to manual or semi-automatic options, which leads to increased productivity. This is one of the reasons why automatic machines are utilized.

-

Cost Savings: Despite having higher initial costs, automatic machines reduce labor expenses and minimize material waste due to precise film usage, which results in cost savings over the long term.

-

Enhancement of Product Presentation: Automated sealing and shrinking processes guarantee that products are tightly wrapped with minimal wrinkles, which enhances the visual appeal of the products when they are displayed on store shelves.

Selecting a Reliable Supplier

Choosing a reputable supplier is as crucial as selecting the right shrink film machine. Ensure the supplier offers reliable customer support, training, and maintenance services to maximize machine uptime and operational efficiency.

Conclusion

Selecting the right shrink film machine involves careful consideration of production requirements, product characteristics, and operational efficiencies. Whether opting for a manual, semi-automatic, or automatic machine, businesses can enhance packaging quality, reduce costs, and improve overall efficiency. By understanding these factors and benefits, businesses can make informed decisions that align with their packaging needs and growth objectives.

By following these guidelines, businesses can effectively streamline their packaging operations and ensure products are securely wrapped and presented attractively, thus enhancing customer satisfaction and brand reputation.